OUR SERVICES

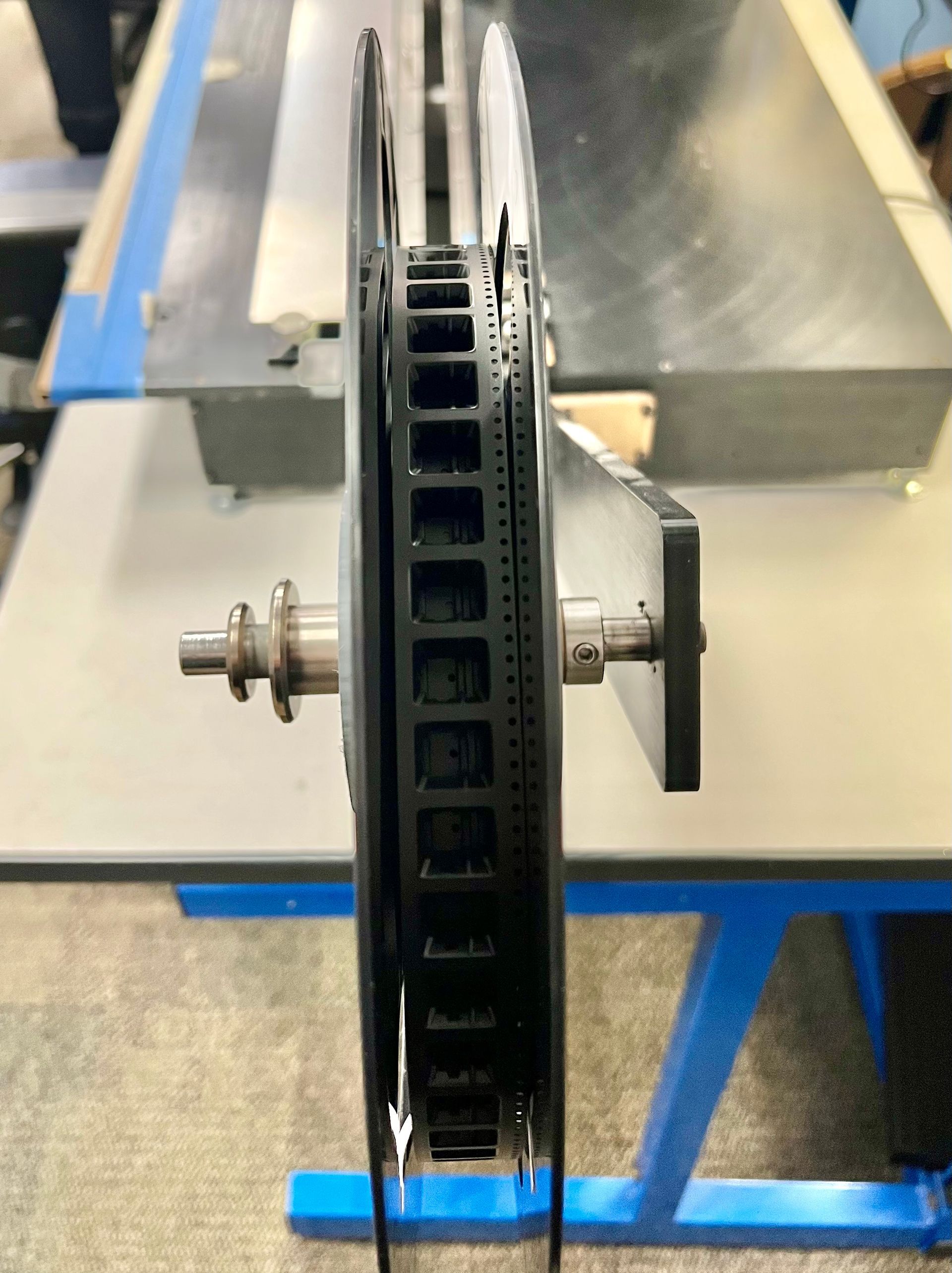

DTR is a full service tape and reel house specializing in the packaging of surface mount devices, manufacturing of carrier tape, and custom tools. Ask about other value add services - we will find a solution for you.

Common Questions

Do I need tape and reel?

Most automated equipment like pick and place machines require surface mount devices and other various components like axials, connectors, radials...etc to be specialty packaged in tape and reel. Typically, the part will have a datasheet

describing the sort of packaging it needs.

How long does it take to tape and reel?

Our typical lead time is 3-5 days. Call us if you are in a bind and need it sooner, if we can get it done faster then we will.

How do I know Dominion can tape my part?

Email us your manufacturers part number and/or a data sheet so we can review it within 24 hours and let you know.

Does Dominion bake moisture sensitive (MSL) parts?

Yes, we do. We will review your datasheet confirming how long they need to baked for and to what moisture sensitivity level.